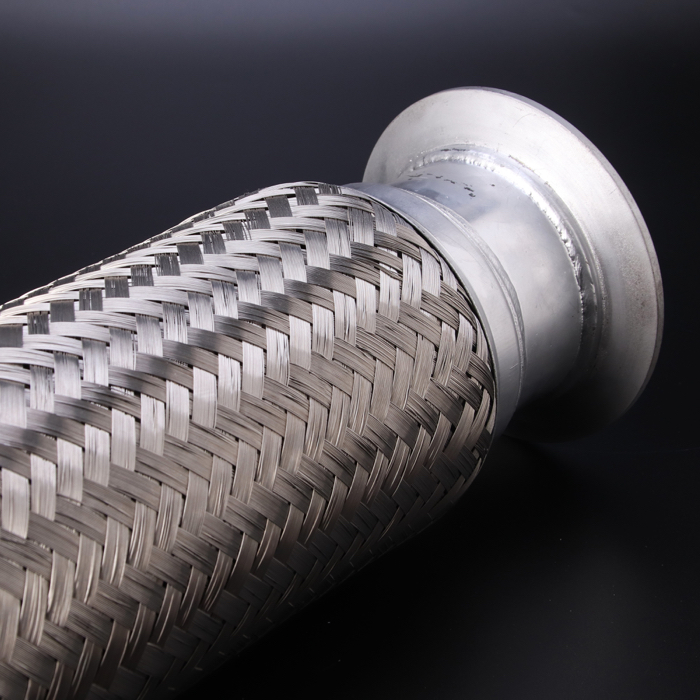

OEM Automobile Stainless Steel Silence Exhaust Flexible Pipe for Car

OEM Automobile Stainless Steel Silence Exhaust Flexible Pipe for Car

share to:

| Origin | China |

| Material | Steel |

| MOQ | 1500 Pieces |

| Certification | CE, RoHS, ISO 9001 |

| Application | Car |

| OEM/ODM | Accepted |

| Component | Exhaust Tail Pipe |

| Discharge Standard | Euro IV |

| HS Code | 8307100000 |

| Production Capacity | 10000 Pieces per Month |

| After Sale Service | 1 Year |

| Main Market | East Asia/Europe/Middle East/North Americ |

| Transport | By sea or by air |

| Packing | Carton boxes or wooden boxes As customer’s specific requirements |

| Delivery Time | 10-20 days after payment |

Product Details

Product Description

Exhaust flex pipes are specialized components engineered to manage movement, vibration, and thermal expansion in exhaust systems. Constructed from flexible and durable materials, such as stainless steel, they play a crucial role in preventing damage and minimizing noise caused by engine vibrations and high temperatures.

Applications

Automotive Industry

- Vehicle Exhaust Systems: Flex pipes are integral to cars, trucks, and motorcycles, absorbing engine vibrations and accommodating thermal expansion. This reduces stress on the exhaust system, prevents leaks, and enhances durability.

- Performance Upgrades: In high-performance vehicles, flex pipes ensure flexibility and safeguard the exhaust system during aggressive driving conditions.

Industrial Equipment

- Machinery Exhaust: Flex pipes are widely used in industrial machinery to manage vibrations and thermal expansion, ensuring durability and reliability over prolonged use.

- Generator Exhaust Systems: These pipes minimize vibrations and handle movement in power generators, enhancing the system’s efficiency and longevity.

Marine Applications

- Marine Engines: Designed for boats and marine engines, flex pipes absorb vibrations and thermal expansion, protecting the exhaust system from damage in challenging marine environments.

- Exhaust System Flexibility: They provide necessary flexibility to accommodate engine movements and reduce stress on the vessel’s hull.

Aerospace Industry

- Aircraft Engines: Flex pipes are employed in aircraft exhaust systems to handle vibrations and thermal expansion, maintaining structural integrity under varying flight conditions.

- Spacecraft Applications: Built to withstand extreme temperatures and vibrations, flex pipes are essential for the demanding environments encountered in space travel.

Construction and Heavy Equipment

- Construction Machinery: Used in heavy equipment such as bulldozers and excavators, flex pipes manage engine vibrations, preventing damage to the exhaust system and prolonging operational life.

- Heavy-Duty Vehicles: Flex pipes ensure resilience in large vehicles like dump trucks and loaders by absorbing vibrations and accommodating thermal expansion in their exhaust systems.

Exhaust flex pipes are a versatile and indispensable solution across industries, ensuring efficiency, durability, and optimal performance in a wide range of demanding applications.

| Inner Diameter | Overall Length | Inner Diameter | Overall Length | Inner Diameter | Overall Length |

| I.D | O/L | I.D | O/L | I.D | O/L |

| 1-3/4 ” (45mm) | 4 ” (102mm) | 2-1/2 “(63.5mm) | 4 ” (102mm) | 43mm | 120mm |

| 6 ” (152mm) | 6 ” (152mm) | 165mm | |||

| 8 ” (203mm) | 8 ” (203mm) | 180mm | |||

| 9 ” (230mm) | 9 ” (230mm) | 50mm(52mm) | 120mm | ||

| 10 ” (254mm) | 10 ” (254mm) | 165mm | |||

| 11 ” (280mm) | 11 ” (280mm) | 54.5mm | 120mm | ||

| 2″(51mm) | 12 ” (305mm) | 12 ” (305mm) | 150mm | ||

| 4 ” (102mm) | 3 “(76.2mm) | 4 ” (102mm) | 180mm | ||

| 6 ” (152mm) | 6 ” (152mm) | 200mm | |||

| 8 ” (203mm) | 8 ” (203mm) | 250mm | |||

| 9 ” (230mm) | 10 ” (254mm) | 60mm(61mm) | 160mm | ||

| 10 ” (254mm) | 12 ” (305mm) | 200mm | |||

| 2-1/4 ” (57.2mm) | 11 ” (280mm) | 6 ” (152mm) | 240mm | ||

| 12 ” (305mm) | 3-1/2″ (89mm) | 8 ” (203mm) | 65mm | 150mm | |

| 4 ” (102mm) | 10 ” (254mm) | 200mm | |||

| 6 ” (152mm) | 12 ” (305mm) | 70mm | 100m | ||

| 8 ” (203mm) | 4″ (102mm) | 8 ” (203mm) | 120mm | ||

| 9 ” (230mm) | 10 ” (254mm) | 150mm | |||

| 10 ” (254mm) | 12 ” (305mm) | 200mm | |||

| 11 ” (280mm) | ID 25~150mm OL 100~400mm Customized size, design, drawing and logo are welcome ! |

||||

Construction and Structure

Components

- Bellows + Double Braid + Nipple + Cap

- Bellows with Outer Braid / Bellows with Inner Braid

- Bellows with Interlock / Bellows with Nipples

Customization: Tailored structures are available to meet specific application requirements.

Functions of Components

- Bellows: Provides a flexible connection and absorbs shocks.

- Outer Braid: Ensures pressure resistance and protects the bellows.

- Inner Braid or Interlock: Directs exhaust flow, shields the bellows, and reduces engine noise.

- Caps: Securely connect the outer braid to the bellows for enhanced stability.

Size and Specifications

Inner Diameter (ID)

- Available in sizes ranging from 1″ to 6″.

Overall Length

- Options range from 4″ to 17″.

Standard Inner Diameter (ID) Options

- Imperial Sizes:

1-3/4″ (45mm), 2″ (51mm), 2-1/4″ (57.2mm), 2-1/2″ (63.5mm), 3″ (76.2mm), 3-1/2″ (89mm), 4″ (102mm) - Metric Sizes:

43mm, 50mm, 52mm, 54.5mm, 60mm, 61mm, 65mm, 70mm

Standard Overall Length Options

- Imperial Sizes:

4″ (102mm), 6″ (152mm), 8″ (203mm), 9″ (230mm), 10″ (254mm), 11″ (280mm), 12″ (305mm) - Metric Sizes:

120mm, 165mm, 180mm, 200mm, 240mm, 250mm

Customization: Tailored sizes, structures, designs, drawings, and logos are available to suit diverse application needs.

Functions and Features

Corrugated Tube Construction

- Manufactured using a double-layer hydraulic pressure process with water as the forming medium, ensuring superior sealing performance and flexibility.

- Optimizes exhaust system functionality for a reliable connection.

Flexible Connection

- Installed between the engine exhaust manifold and muffler purifier to enhance shock absorption and noise reduction in the exhaust system.

Applications

- Suitable for light-duty vehicles, mini cars, coaches, trucks, and motorcycles.

Performance Benefits

- Reduces noise and air pollution.

- Simplifies installation and extends the lifespan of the exhaust system.

With advanced construction, customizable options, and high-performance features, Genleelai Autoparts’ flexible exhaust components deliver the ideal solution for a wide range of automotive applications.

Related Products

Contact Us

Get In Touch With Us

If you have other questions, please leave your email, and professional staff will answer your questions.

A professional auto parts manufacturer

GENLEELAI Technology (Qingdao) Co., Ltd.

Copyright © 2020. All rights reserved.