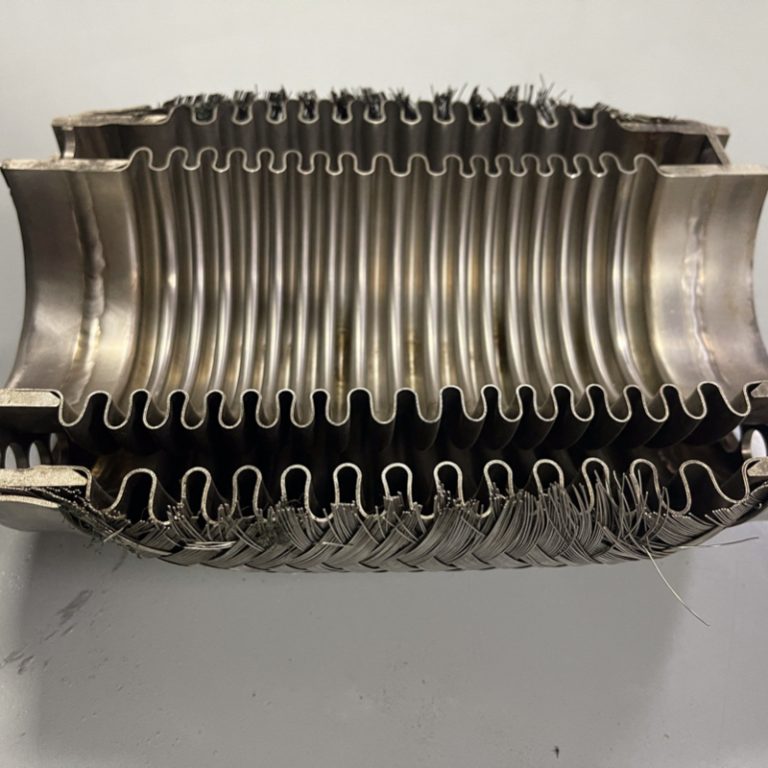

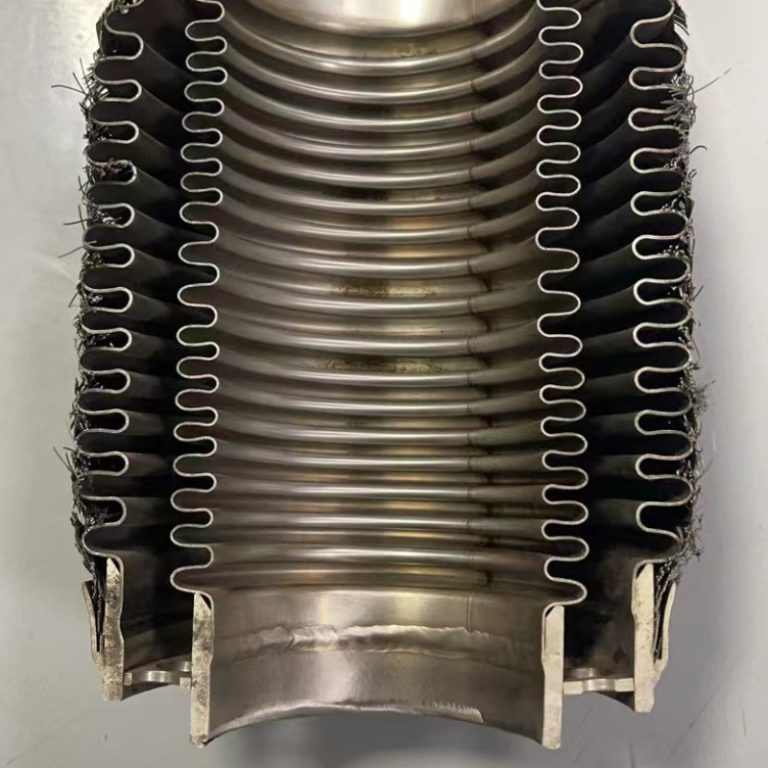

Our GLL 316L Flex Exhaust Bellows is designed for marine exhaust systems, offering exceptional flexibility, durability, and corrosion resistance. Made from high-quality 316L stainless steel, this flexible bellow effectively absorbs engine vibrations, compensates for thermal expansion, and reduces stress on exhaust piping.

Key Features

- Premium 316L Stainless Steel: Superior resistance to corrosion, ideal for harsh marine environments with saltwater exposure.

- High-Temperature Resistance: Operates efficiently in extreme temperatures ranging from -196°C to 600°C.

- Flexible & Durable Design: Engineered to absorb vibrations, thermal expansion, and mechanical movement, extending the lifespan of exhaust components.

- Reinforced Structure: Available with single or double-layer bellows and optional wire mesh or braided reinforcement for added strength.

- Customizable Connections: Offered in flange, quick coupling, or threaded ends to suit various installation requirements.

- Industry Compliance: Meets DNV, LR, ABS, and ISO 15540/15541 fire resistance standards, ensuring safety and reliability.

Applications

1. Automotive Industry

- Vehicle Exhaust Systems: Flex pipes play a vital role in cars, trucks, and motorcycles, absorbing engine vibrations and accommodating thermal expansion. This helps reduce stress on the exhaust system, prevents leaks, and enhances overall durability.

- Performance Upgrades: In high-performance vehicles, flex pipes maintain system flexibility and protect the exhaust from stress during aggressive driving conditions.

2. Boat equipment

- Machinery Exhaust: Used extensively in industrial machinery, flex pipes manage vibrations and thermal expansion, ensuring long-term durability and reliability.

- Generator Exhaust Systems: These pipes reduce vibrations and handle movement in power generators, improving system efficiency and extending its service life.

3. Marine Applications

- Marine Engines: Flex pipes are designed for boats and marine engines, absorbing vibrations and thermal expansion to protect the exhaust system in harsh marine environments.

- Exhaust System Flexibility: These pipes provide the flexibility needed to accommodate engine movements, reducing stress on the vessel’s hull.

4. Aerospace Industry

- Aircraft Engines: In aircraft exhaust systems, flex pipes manage vibrations and thermal expansion, maintaining the structural integrity of the system under various flight conditions.

- Spacecraft Applications: Designed to withstand extreme temperatures and vibrations, flex pipes are critical for the demanding environments encountered in space travel.

5. Construction and Heavy Equipment

- Construction Machinery: Flex pipes are used in heavy equipment such as bulldozers and excavators, managing engine vibrations to prevent damage and prolong the operational life of the exhaust system.

- Heavy-Duty Vehicles: In large vehicles like dump trucks and loaders, flex pipes ensure the exhaust system’s resilience by absorbing vibrations and accommodating thermal expansion.

Exhaust flex pipes are a versatile and essential solution for a wide range of industries, ensuring efficiency, durability, and optimal performance in demanding applications.